Bio-based Lightweight Design

Cost-efficient. Sustainable. Aesthetic.

We deliver outstanding natural fiber

composites for your lightweight application.

Making circular materials the new industrial standard.

Boosting your lightweight application with BEHtec bio-based materials

Weight reduction

-50%

Our bio-based materials are up to 50% lighter than conventional composite materials.

Reduce energy consumption, improve handling, and optimize performance without compromise.

Cost-efficient

-60%

Less waste due to material offcuts. Save up to 60% and avoid costs due to non recycable waste.

Our tailored prepreg manufacturing is automated at industrial scale - saving costs on manual activities.

Sustainable

-90%

Reduce your CO₂ footprint up to 90% with our bio-based materials and highly efficient manufacturing process.

We use renewable raw materials from regional production in Europe.

Lightweight Solutions

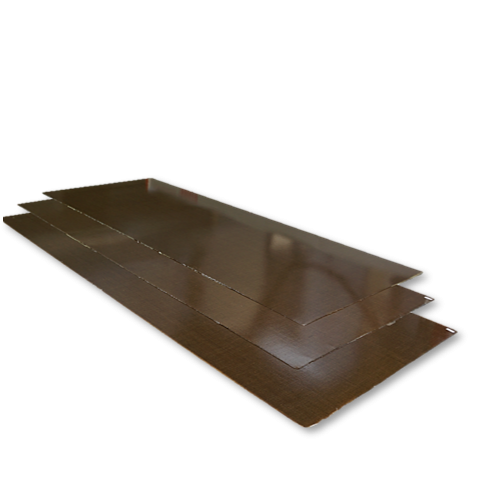

Tailored Prepregs

We deliver ready-to-use natural fiber prepregs with complete layer structure. Tailored to your requirements and optimized for scalable manufacturing.

Component Manufacturing

We manufacture lightweight components with outstanding performance. A unique combination of function, form and sustainability. Ready to elevate your product experience.

Materials as a Service

From first prototype to scalable material sourcing - we support your development process with technical expertise. BEHtec empowers you to build lighter, faster, and more responsibly.

Applications

BEHtec enables high-performance lightweight components in multiple industries – always tailored to the specific mechanical, aesthetic and sustainability requirements of your product. Discover where our materials create real impact.

Camper

Roof modules, interior panels, and furniture elements – combining low weight, design freedom, and a natural look.

Cargo Boxes

Lightweight, durable, and weather-resistant box systems – designed for urban mobility and made from natural fiber composites.

Commercial Vehicles

Interior and exterior paneling solutions for vans, trucks, and fleet vehicles – optimized for weight reduction, durability, and clean design.

Space

Satellite panels and subsystems enabling low weight, tailored functionality and Clean Space compatibility.

Aviation

Panel systems for cabin interiors and lightweight structural parts – engineered to meet strict weight and safety requirements.

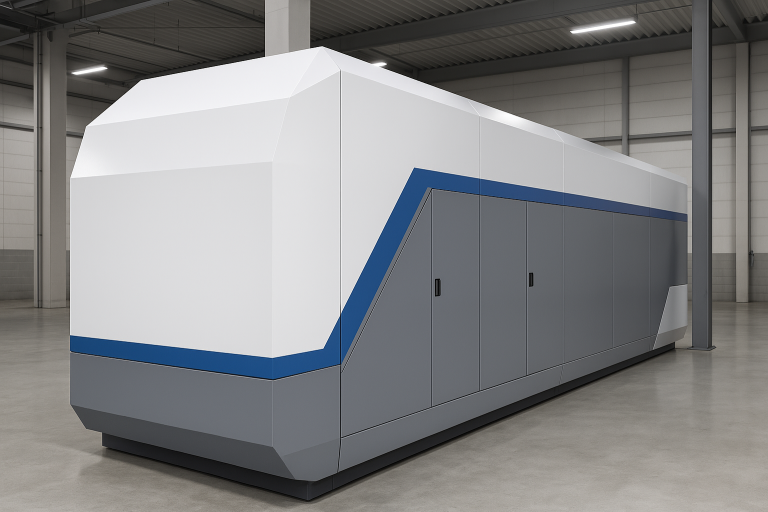

Industrial Plants

Covers, housings, and wall elements for industrial machinery – lightweight, acoustic dampening, and easy to handle.

BEHflow Technology

Near net shape minimizing waste

Cutting

Impregnating

Layer build-up with minimal consumables

Stacking

Innovative process boosting material quality

Curing

Easy to integrate into existing workflows

Our Partners

We are proud to have developed our research work at the University of Stuttgart into a successful EXIST research transfer project with the support of the Technology Transfer Initiative (TTI), the Innovation Campus Mobility of the Future (ICM) and the Transfer Center of the University of Stuttgart (TRACES).

Bio-based Materials

where Nature meets Engineering

We use renewable raw materials like flax and hemp, sourced regionally within Europe.

Our composites combine these natural fibers with bio-based resin systems to create lightweight, high-performance materials with a significantly lower environmental impact.

Thanks to the low density of natural fibers, our solutions reduce weight by up to 50% compared to aluminum and by around 30% compared to glass fiber-reinforced plastics – enabling more efficient, sustainable product design across industries.

Connect with us

Together, we are setting standards in sustainable lightweight construction - for a sustainable and resource-saving industry.

Dominique Bergmann

Prototyping

Dominique has over 10 years of experience in prototyping and project management, with a strong background in mobility and aerospace applications.

Mathias Engelfried

Technology Development

Mathias specializes in natural fiber composites and process simulation, combining material know-how with automation expertise.

Klaus Heudorfer

Process Automation

Klaus brings 10+ years of experience in FRP process development, cycle time optimization, and quality control for industrial production.

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.